Press release for the Meeting of the Material

Discover the press release below regarding Flaxcomp®, the biocomposite material created by DEMGY, published for the Meeting of the Material trade show dedicated to innovative materials for architecture, design, decoration and interior design.

I. Introducing DEMGY

1. Its history, expertise and development priorities for the future.

For more than 70 years, the DEMGY's DNA has included determination and a spirit of entrepreneurship, success and innovation.

Since its inception, the Group, which specialises manufacturing technical plastic and composite parts, has evolved and grown thanks to the boldness and professionalism of its teams and to its unique Multiplasturgy® concept:

Today, the DEMGY is one of Europe's leading specialists in the design and manufacture of high-performance technical plastic and composite parts as replacements for metal parts.

This is how the company meets the needs of equipment manufacturers, builders and designers.

The Group's priorities for the future are:

- International growth: DEMGY's objective is to increase export sales from 55% to 70% by 2025.

- Digital transformation to become a major player in Industry 4.0.

- Being the company that initiates the transition to a sustainable use of plastics through the circular Multiplasturgy® concept.

For all the latest news from DEMGY, visit our brand new website www.demgy.com and our LinkedIn page.

DEMGY in figures:

The Group employs 620 people

It completes over 615 projects each year

With customers in more than 25 countries

For a 2019 turnover of €66 million

II. DEMGY’s expertise.

1. The Multiplasturgy® concept.

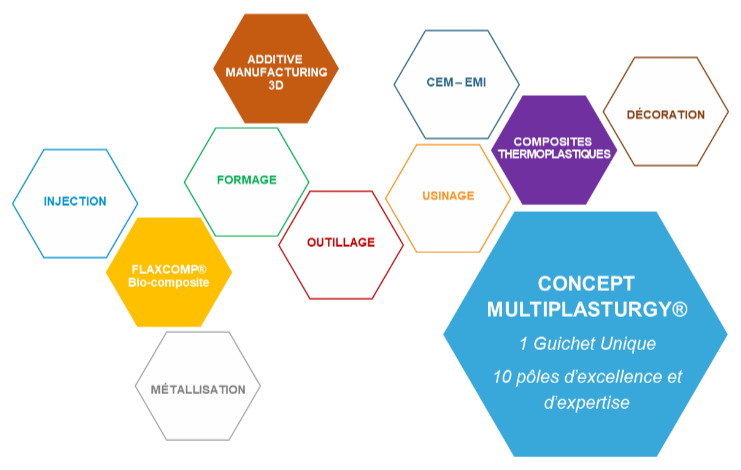

The Group's technologies and services are combined in its unique Multiplasturgy® concept. The Multiplasturgy® concept is the core of the DEMGY Group's powerhouse and the driving force behind its growth, based on a concept that encourages the exchange of information and the pooling of skills.

The Multiplasturgy® concept is the shortest, most efficient and most innovative way to offer global, differentiating and value-creating solutions. The services range from assistance in the choice of materials to co-design and production of sub-assemblies and assemblies.

All this expertise positions DEMGY as one of the leading French specialists in substituting plastic for metal.

2. Metal to plastic solutions®.

There are many benefits to replacing metal with HPP - High Performance Polymers - plastics: weight savings, mass savings and 90% recyclability of parts.

In terms of ISO design, here are some examples of lightening of materials by replacing metal with high performance plastics and composites:

- Aluminium, density = 2.7 g/cm3

- HP (High Performance) plastic: density = 1.3 g/cm3

- So in terms of ISO design, we could save up to 50% mass. In the context of optimised design, a weight saving of 20% to 30% should be expected.

The Group's expertise ranges from a recognised knowledge of materials (plastics, high performance polymers and composites) to the mastery of various implementation technologies for producing parts and sub-assemblies covering a wide range of applications:

- 3D mass manufacturing

- Smart Plastic Products

- Biocomposite

- High precision machining of plastics & composites

- Thermoplastic moulding (TP) & thermoset (TS) moulding, micro-injection, overmoulding and bi-material

- Forming, thermoforming, RTM & SMC (Resin Transfer Molding & Sheet Molding Compound) and stamping of thermoplastic composites outside the autoclave

- Design & manufacture of moulds & tooling and parts

- Metallisation of thermoplastic composite plastics, electro-magnetic compatibility & absorbers

- Surface treatment, decoration and assembly

Our certifications:

ISO 9001

ISO 13 485

ISO 14 001

EN/AS 9100

AQAP 2110

IATF 169493

Strategic industrial partnerships to boost excellence. DEMGY is actively developing its ecosystem with partnerships - industrial, economic and digital - aimed at strengthening its excellence in many fields.

III. "Innovation is our lifeblood."

Innovation is a differentiating factor for DEMGY. Based on a single customer project, the Group's expertise in material and composite engineering enables it to offer adapted, original and high-performance manufacturing solutions in key sectors such as Smart Plastic Products, high-performance materials, additive manufacturing and biocomposites.

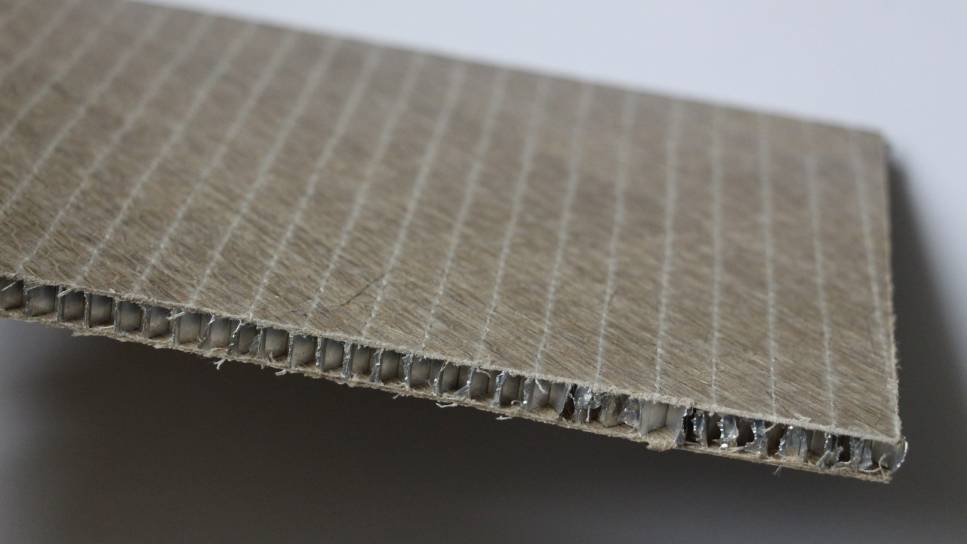

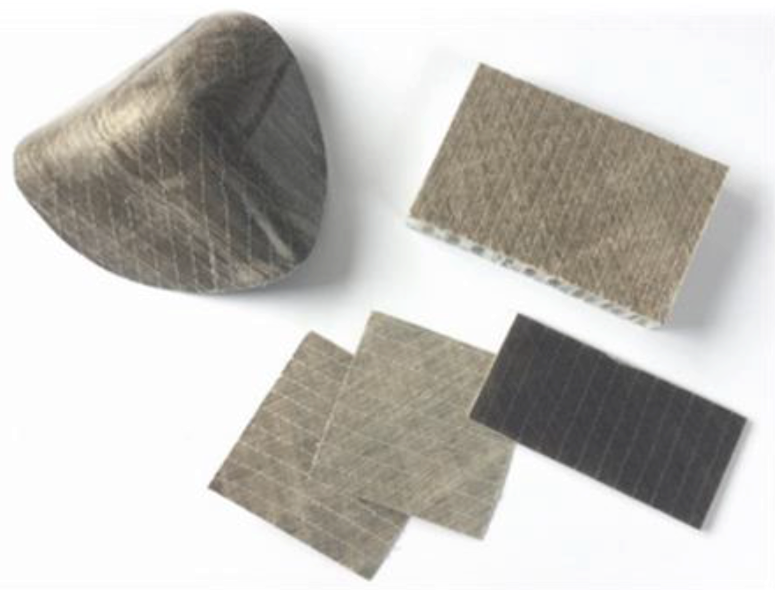

DEMGY is indeed able to offer 100% recyclable part manufacturing by thermoforming biocomposites with Flaxcomp® - ‘flax’ referring to the flax plant and ‘comp’ for composite - composed of flax and a resin made from corn starch (PLA) or castor oil (PA11).

Flaxcomp® is a range of recyclable technical biocomposites made from flax fibre:

- Flax fibre is grown by farmers belonging to the Normandy cooperative Terre de Lin (TDL). A local, reliable and transparent manufacturing chain.

- Flax fibre is worked by TDL Technique and woven into a fabric

- The flax fabric has a recyclable plastic resin added (resin added by DMG or TDL Technique) and is transformed into a flax-reinforced product by DEMGY. A short and local supply chain based in Normandy

- A solution for:

- Meeting new societal needs and expectations

- Proposing a new composite range with eco-materials

- Providing new industrial solutions adapted to meet requirements

Flaxcomp® is both an alternative to fibreglass, because it is 24% lighter than glass, and a TRUE answer to the issue of plastic recyclability.

Flaxcomp® uses flax: an ultra-light, rigid, strong, resistant and durable material that fits into a three-dimensional logic:

- Eco-responsible

- Eco-sustainable

- Eco-designable

Flax biocomposite is defined by its high quality, its ecological awareness and its innovative aspect - an innovative and natural material (linen combined with corn starch resin - PLA)

- 100% made in France

- 100% recyclable

- THE durable plastic

Flaxcomp® is compatible with traditional manufacturing methods while meeting environmental demands (recyclability, life cycle management and carbon footprint).

Flax fibre has important properties in terms of vibration absorption, sound insulation and an eternal life cycle (recyclable).

Share this page